Aluminum truss is a popular choice for building structures that require strength, durability, and flexibility. It is commonly used in the construction of stages, lighting rigs, and exhibition stands due to its lightweight construction, ease of assembly, and structural strength. Creating aluminum truss can seem like a daunting task, but with the right tools and knowledge, it’s a relatively straightforward process.

Types of Aluminum Truss

There are several types of aluminum truss, each with their own unique design and purpose. Here are some of the most common types:

- Single Truss: One single truss line used for light-duty installations.

- Double Truss: This type of truss consists of two parallel beams connected by rungs. It is commonly used for creating lighting grids and small structures.

- Triangular Truss: As the name suggests, this truss is made up of triangular sections. It is often used for creating larger structures, such as stages and exhibition stands.

- Box Truss: This truss is made of square sections and is commonly used for creating structures that require a high weight-bearing capacity.

- Rectangular Truss: This truss system is also used for large span structures with high loading demands.

- Special Truss (such as Pre-Rig Truss): This type of truss can be equipped with a specific transport dolly that makes it easier to move the pre-rigged truss around, even with equipment, such as lights, attached to it.

Aluminum properties

Aluminum is a lightweight, durable, and corrosion-resistant metal that is commonly used in the construction industry. There are several properties of aluminum that make it an ideal material for truss:

- Strength: Aluminum has a high strength-to-weight ratio, which means it is strong but lightweight. This makes it ideal for creating structures that need to support a lot of weight.

- Durability: Aluminum is highly resistant to corrosion, which means it can withstand exposure to the elements without rusting or deteriorating.

- Versatility: Aluminum can be easily shaped and moulded into different forms, making it ideal for creating truss of various shapes and sizes.

Knowing the different types of aluminum truss and its properties can help you choose the right one for your project. By selecting the appropriate truss, you can ensure that your structure is strong, durable, and able to withstand the test of time.

Designing Aluminum Truss

Design Principles

When designing aluminum truss, there are some important principles to consider. First and foremost, the truss must be able to support the weight of the intended load. This requires careful consideration of the materials used, as well as the dimensions and spacing of the truss members.

Second, ensuring the truss is stable and able to withstand external forces such as wind or seismic activity. This can be achieved using diagonal bracing and other reinforcement techniques.

And finally, the design should also consider any aesthetic considerations, such as the desired shape or appearance of the truss. This may involve the use of curved or angled members, or other design features that help to achieve the desired look.

Materials and Tools Required

Aluminum Alloys

Creating aluminum truss requires the use of specific aluminum alloys. It starts with bauxite extraction from which aluminum is produced. Pure aluminum is then processed into different alloys, which are made into ingots, and later, to different profiles.

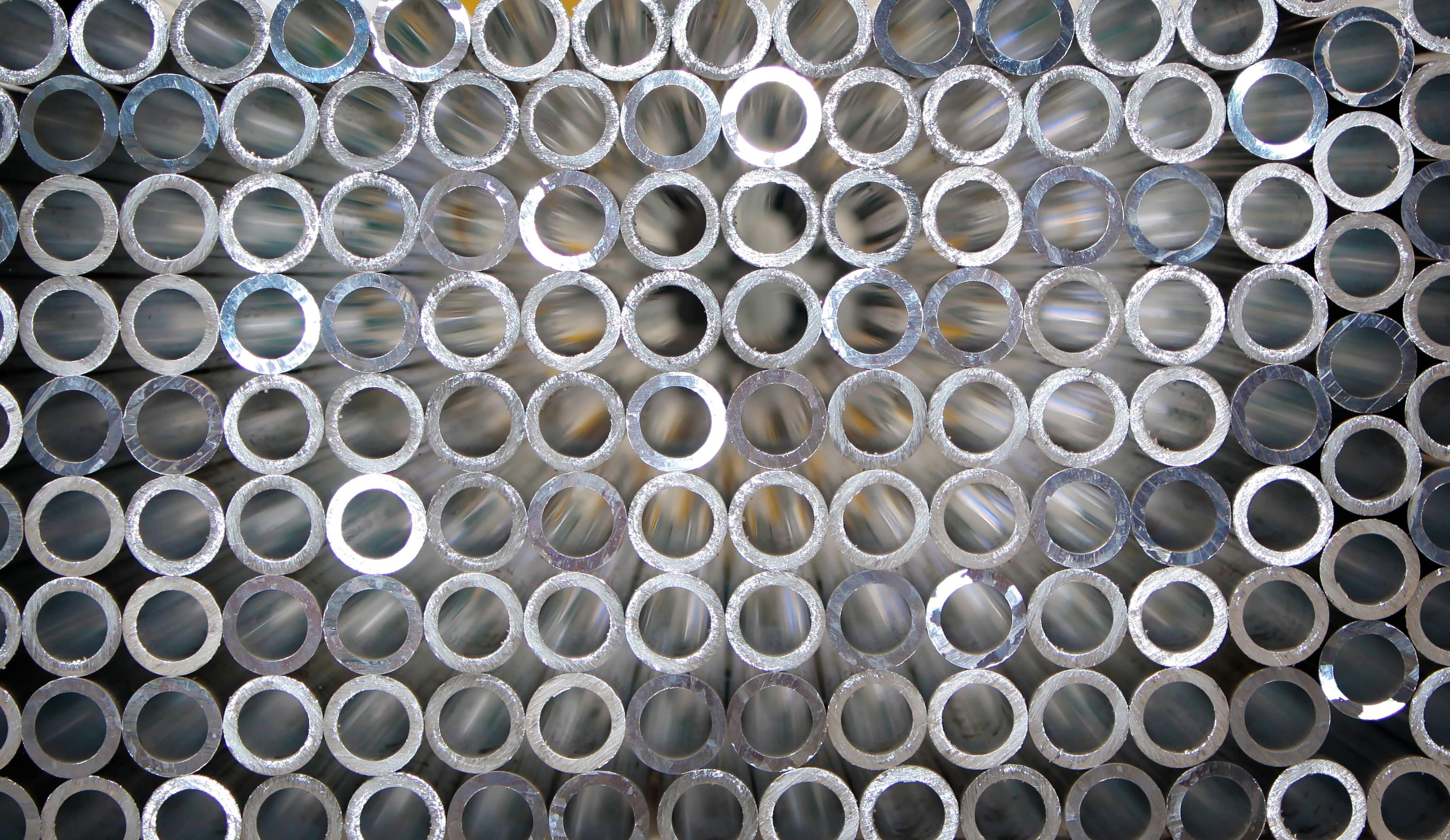

Tubes are made from EN AW-6060, and mainly, EN AW-6082 alloys. For sheets, EN AW-5754 and EN AW-5083 allows are used. These alloys are known for their high strength-to-weight ratio, corrosion resistance, and easy weldability.

HydroREDUXA 4.0 is a low-carbon aluminum that uses renewable energy sources, such as hydro power, wind, and solar, to reduce the carbon footprint of the aluminum.

Fabrication Tools

Several tools are required to create aluminum truss. These include the following:

- Saw: Cuts the aluminum extrusions to the desired length.

- Drill: Creates holes in the aluminum extrusions for bolts and other accessories.

- Special Tooling: Holds the aluminum extrusions in place during the welding process.

- Automated Welding Machine: Programmed to make precision welds and can operate around the clock.

- CNC Machine: An abbreviation of “Computed Numerically Controlled welding” is pre-programmed to execute a sequence of complex processes to precise standards.

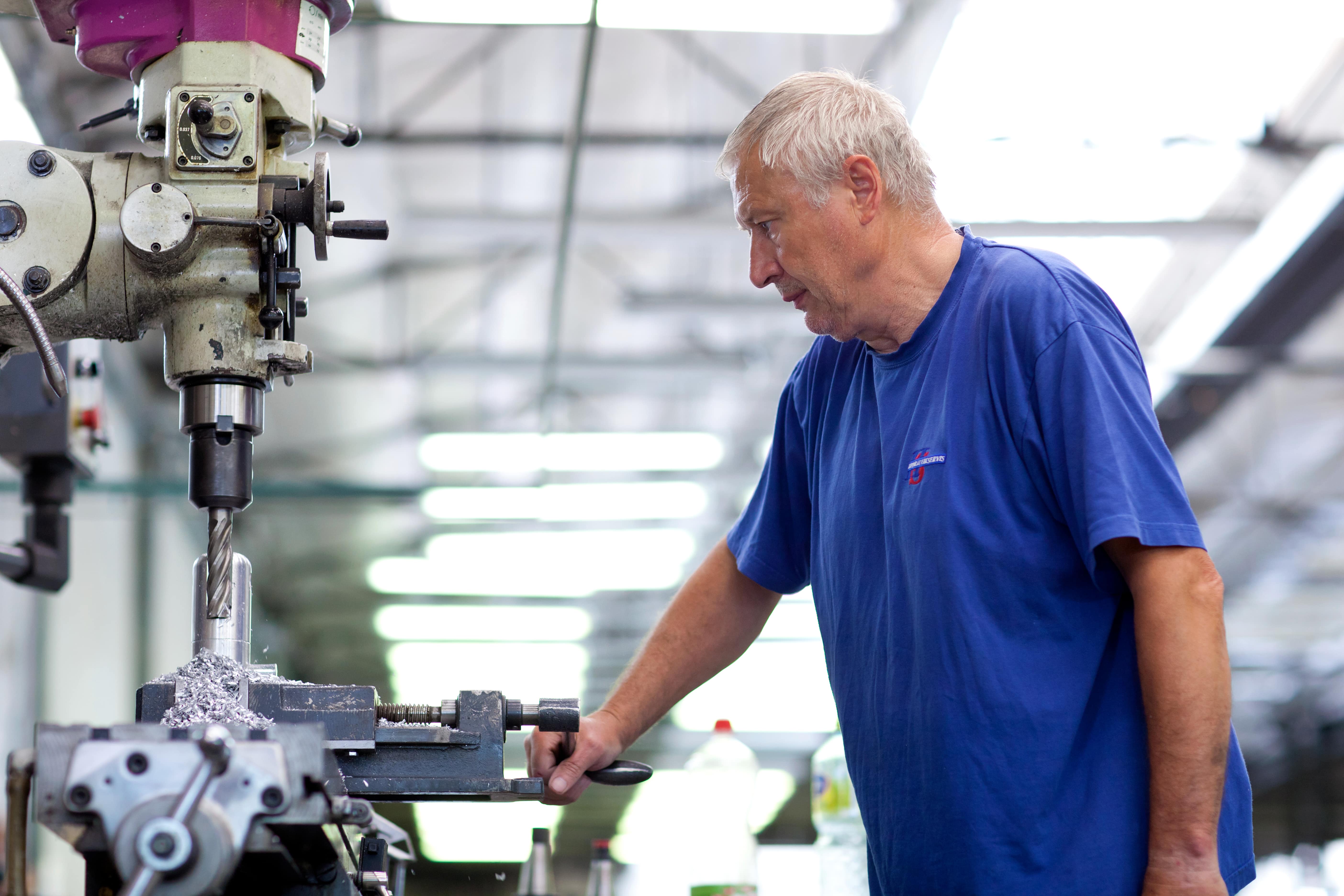

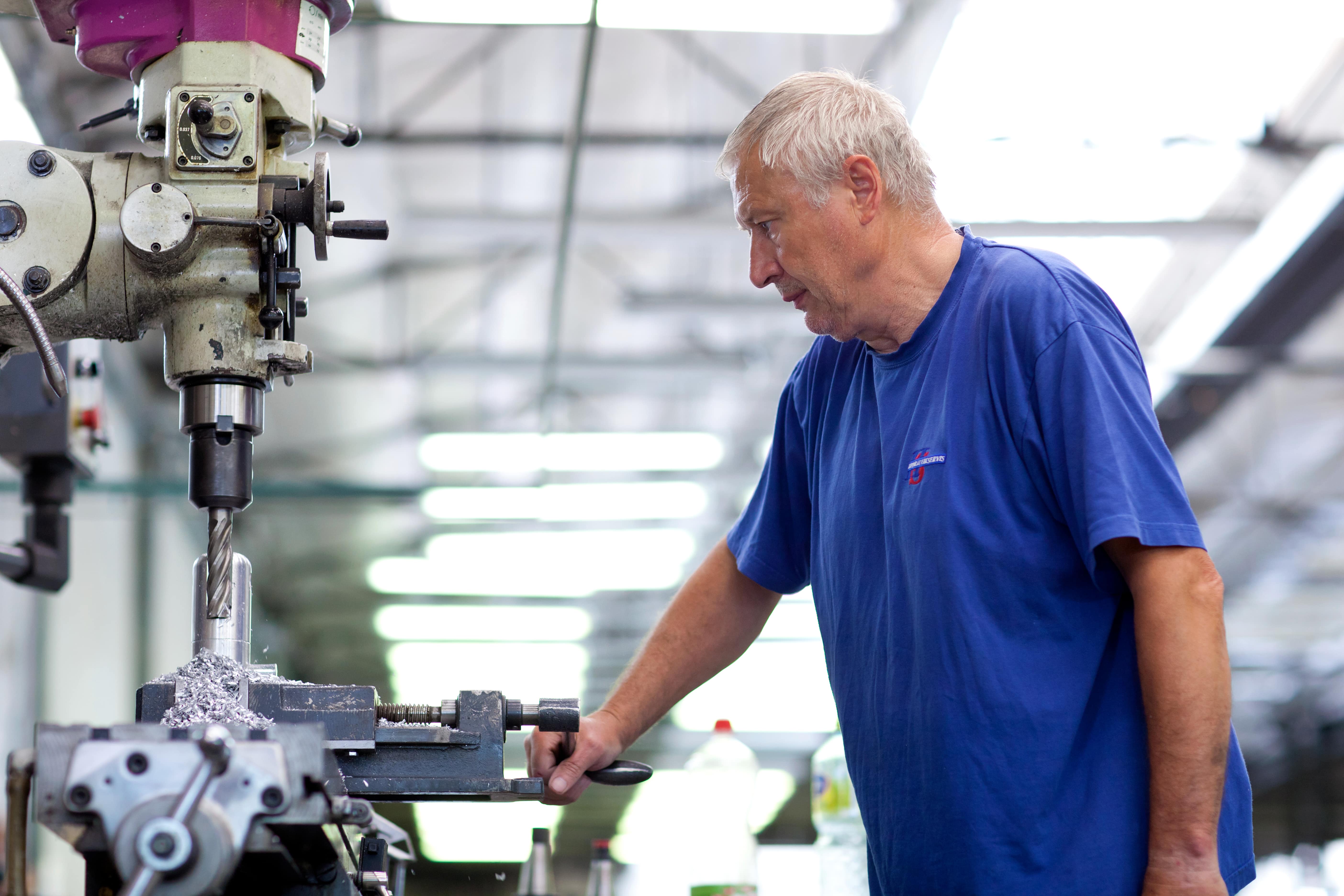

- Milling Machines: Rotary cutters on these machines remove material from pieces of truss or make holes in more complicated shapes. Excess material can be cut out at any angle.

In addition to these tools, safety equipment such as gloves, goggles, and a welding helmet should also be used during the fabrication process.

The Fabrication Process

Extruding the Tubes

The first step in creating an aluminum truss segment is the extrusion of raw aluminum material into shapes necessary to produce the desired truss. This is usually done by extruding the aluminum into tubes of various sizes and shapes. They consist of larger tubes that run the length of the truss and smaller diameter tubes that make up the cross bracing (sometimes known as webbing). These are extruded in long lengths, which requires them to be cut to size before they can be used in the truss assembly process. Other pieces and accessories may require additional machining.

Cutting The Tubes

The next step in creating an aluminum truss is to cut the aluminum tubes to the required length. This is done using a saw or a cutting machine. The tubes are then machined to remove any burrs or rough edges. This is important to ensure that the tubes fit together properly during assembly. Lathe turning parts are used to shave the tubes down.

Welding Techniques

Once the tubes have been cut and machined, they are welded together to form the truss. There are several welding techniques that can be used, including TIG welding, MIG welding, and arc welding. TIG welding is often preferred for aluminum trusses because it produces a clean, precise weld. Welders are trained regular, having to pass an exam every two years to remain certified.

Welding Safety

Welding is an essential part of creating aluminum trusses. However, it can also be a hazardous process if proper safety precautions are not taken. The following safety guidelines should be followed when welding aluminum trusses:

- Always wear appropriate personal protective equipment (PPE), such as welding gloves, safety glasses, and a welding helmet.

- Ensure that the welding equipment is in good condition and has the appropriate settings for welding aluminum.

- Avoid welding in areas with flammable materials or gases.

- Ensure that the work area is well-ventilated to avoid inhaling harmful fumes.

- Use a welding curtain or screen to protect others from the welding arc.

- Always follow proper welding techniques and guidelines to avoid injury or damage to the truss.

By following these safety guidelines, you can ensure that creating aluminum truss is a safe and efficient process.

Overall, the fabrication process for creating an aluminum truss segment requires precision and attention to detail. By following the proper cutting, machining, welding, and assembly techniques, a high-quality segment can be created that is strong, durable, and reliable.

Handling and Lifting

When manufacturing aluminum truss, it is important to take into consideration its weight and size. Always use the appropriate lifting equipment and techniques to avoid injury. The following safety guidelines should be followed when handling and lifting aluminum truss:

- Always wear appropriate PPE, such as gloves and safety glasses.

- Ensure the lifting equipment is in good condition and has the appropriate weight capacity for the truss.

- Use lifting equipment such as cranes, hoists, and forklifts to lift the truss.

- Avoid overloading the lifting equipment or exceeding the weight capacity of the equipment.

- Ensure the truss is properly secured to the lifting equipment before lifting.

- Always follow proper lifting techniques such as keeping your back straight and using your legs to lift.

Quality Control

Inspection Methods

Quality control is a crucial aspect of aluminum truss manufacturing. To ensure that the truss is of the highest quality, various inspection methods are employed throughout the manufacturing process.

One of the most important inspection methods is visual inspection. This involves checking the truss for any visible defects such as cracks, dents, or deformations. Visual inspections are carried out by trained inspectors who have a keen eye for detail.

Another inspection method is dimensional inspection. This involves measuring the truss to ensure that it meets the required specifications and is done using specialized equipment, such as micrometers and callipers.

Testing Procedures

In addition to various inspection methods, testing procedures are also employed to ensure the quality of aluminum truss. One of the most common testing procedures is load testing. This involves subjecting the truss to a load that is greater than it´s intended use to ensure that it can withstand the weight.

Overall, the combination of inspection methods and testing procedures ensures that the aluminum truss is of the highest quality and meets all the required specifications.

Packing and Transporting

Truss is bulky and requires special handling. Proper packaging is crucial to prevent damage during shipping or storage

Protective Measures.

- Foam inserts and wrapping the truss in plastic or bubble wrap can ensure their safety.

- Purchase liability insurance with your shipper, since damage to any segments by a rogue forklift could compromise your entire structure.

Installation

Connecting Truss Systems

Before beginning the installation process, it is important to ensure that you have all the necessary connecting accessories. The type of accessories will vary depending on the type of truss being used, so it is important to understand how the truss fits together and what accessories to use to ensure a safe and secure installation.

For example, truss with bolt connections will need the appropriate bolts, nuts, and washers to be connected together, while some other types of trusses have receivers welded onto the ends of the main tubes, which are then connected by inserting a conical or fork connector into the receiver and securing it in place with a locking pin system.

Installation Process

Installation can vary depending on the design and the type of truss. In any case, it is always important to understand how the structure will fit together and have an appropriate plan with the right equipment on site to ensure the structure comes together as efficiently and safely as possible. In larger applications, equipment like lift-trucks and truss lifting towers may be needed to erect the structure, while smaller applications may only require a small team of people to secure the truss in place.

Maintenance and Repairs

Routine Maintenance

To ensure the longevity and optimal performance of aluminum truss structures, routine maintenance is essential. The following are some recommended routine maintenance practices:

- Regularly inspect the truss structure for any signs of wear and tear, such as cracks, dents, or corrosion.

- Clean the truss structure regularly to remove any dirt, dust, or debris that may accumulate on the surface.

- Lubricate all moving parts of the truss structure, such as bolts and nuts, to prevent the build-up of rust and corrosion.

- Check all connections and joints to ensure they are tight and secure.

By following these routine maintenance practices, the truss structure will remain in good condition and perform optimally for years to come.

The recipe for bringing truss to life

From sourcing raw materials to quality control and packaging—the process of manufacturing aluminum truss involves several critical steps to ensure a safe, high-quality product. Each stage requires expertise, precision, and attention to detail to ensure the production of a sturdy and durable truss segment.

By following a carefully orchestrated process, manufacturers can produce high-quality aluminum truss that meets the diverse needs of their clientele and delivers the highest level of safety.